Web Exclusive! GMS Drums: Looking Back and Stepping Forward With New York’s Original Boutique

GMS founders Tony Gallino and Rob Mazzella in 2012

GMS founders Tony Gallino and Rob Mazzella in 2012

Web Exclusive!

GMS

Looking Back and Stepping Forward With New York’s Original Boutique

by Michael Dawson

No fancy robots, no marketing focus groups, no overstated advertising campaigns—just great-sounding and great-looking drums, handmade by drummers for drummers. That’s been the GMS way since the Long Island natives Rob Mazzella and Tony Gallino began building custom snare drums twenty-six years ago.

Believe it or not, back in 1987 not many drum companies could claim such a fluff-free hands-on approach to doing business. But there was a clear demand for it, as Rob and Tony soon found out when orders came pouring in after their NAMM Show debut in 1988. From there on out, GMS would be widely regarded as one of the world’s premier custom-shop drum makers.

A lot has changed in the drum market since GMS paved the way for other boutique brands over two decades ago, so we decided to make a trip over to the company’s workshop in Farmingdale, New York, to sit down with Mazzella and talk about how GMS went from a pet project to an internationally recognized brand, and also to get a feel for how he and Gallino are primed to adapt to today’s ever-evolving music industry. Advertisement

DB: Where is GMS in 2013? What’s your focus these days?

Rob: We’ve been taking a page out of Apple’s book by focusing on some specialized products, as opposed to when we used to offer everything. I don’t think that approach works in today’s society. Some companies seem to be a little bit successful with it, but it’s a harder pitch for us to get that customer now. We used to own that market back in the late ’80s and early ’90s, but now we’re having a lot of success with more specialized products, like the Revolution and PVS snares and the Super Vintage series.

DB: How do you come up with new ideas?

Rob: We’re a little bit on the organic side over here. One of the guys in the shop might think of something cool to try, and then one day we start making it. The PVS [Perimeter Venting System], which has a ventilated bottom bearing edge, was developed by one of the guys in the shop, Pete Levine. It was a cool idea, so we tried it and it’s worked out great.

DB: Is the vented bearing edge designed to make the drum more sensitive?

Rob: Yeah. When you hit a drum, you’re moving a column of air. If you have one air hole in the side of the shell, the drum doesn’t resonate fully, because the air escapes. We put the vent hole as close to the bottom head as we can on all of our drums. But with the PVS, the air resonates the bottom head completely before it escapes through a few holes in the bearing edge. Advertisement

DB: How did the Super Vintage, which is designed to sound like classic American drums from the early and middle 1900s, come about?

Rob: We had talked to a couple of drummers who wanted that sound. We did a six-lug snare drum for a guy, to emulate some of the old six-lug drums. The fewer lugs you have, the fatter the drum sounds. We tried the six-lug drum, and it worked. But that’s not a concept we’d put out, because it detunes quickly, so we started working on something that would make a similar sound. We changed our shell makeup and the bearing edges, and then it found itself.

DB: Are all the Super Vintage kits coming with the two-tone duco finish?

Rob: We’ve had guys get them in natural or black, but we thought it would be cool to offer duco as a standard finish. We have four options: black and gold, black and silver, cream and gold, and blue and silver.

DB: Tell us about the Revolution series.

Rob: We actually spray metal inside a wooden shell. It’s a catalyzed process. When it cures, it looks like a casting. We sand and polish it, just like we do to a piece of metal, and the luster comes up. It makes a wood snare drum sound like a metal snare drum, without all the overtones that an all-metal shell would have. If we spray it with brass, it sounds like a brass snare drum. We have a new one in aluminum. Advertisement

DB: Do you still offer your original line, the Grand Master series?

Rob: We do, but we keep it more as a keepsake. A couple people order a kit here and there, but it’s not something we focus on anymore.

DB: Why not?

Rob: People don’t seem to like that look anymore. Also, because the rod and lugs are solid brass, they really increase the weight of the drum.

In essence, the Special Edition lug serves the same purpose without having the rods. We are still able to secure the lug to the shell with one bolt, which we position at the bottom of the lug, where the tension rod meets the receiver. The tension rod, lug, and bolt form an L, so when you tighten the head the tension is absorbed at the bottom of the lug, and it’s not pulling into the shell.

DB: What were you trying to accomplish with the original GM tube lug?

Rob: We were trying to eliminate stress on the shell. When we first started, the way that lugs were mounted on existing drums pulled the lug into the shell, which dampened the vibration. We put that rod between the two lugs so that it counter-pulls to keep tension off the shell.

DB: But sonically, GM and SE series drums are essentially the same.

Rob: Right. Part of the reason we branched off with the Special Edition lug is the visual aspect of it. We’re noted for our finishes, and people wanted to see more of the finish of the shell. The Grand Master lug blocks a lot of it. Advertisement

DB: You introduced the CL series in 1994. What was that designed to do?

Rob: It was designed to be an alternative to the GM and to be a price differential.

DB: But they’re also handmade, right?

Rob: They’re handmade, but since 2004 they’ve been made in a small factory in Taiwan. It’s almost the same setup as we have here at GMS. It’s a family-owned business, and they make all the drums by hand. We couldn’t have found a better place to have the CL series manufactured.

DB: Is the shell construction the same with the CL series as it is with the GM and SE?

Rob: The shell ply is different, but the thickness is the same. We use an 8-ply maple shell on GM and SE drums and a 7-ply maple shell on the CL.

DB: So thickness is the most important factor in a drum shell’s sound?

Rob: The thicker the shell, the higher the pitch. Some companies graduate the thickness of the shells as the drums get bigger, but that doesn’t make sense to us, because the bigger drums should have a deeper tone. Why would you make the shell thicker, which raises the pitch, to achieve a deeper tone?

We design drums mainly from a sonic perspective. That’s why we use 8-ply shells all the way across. That makes a consistent tone, and all the shells are uniform. But we do change the bearing edges as they go around. We start with a sharper edge on smaller toms, and we leave a little more wood touching the head on larger drums, for a fatter tone. Advertisement

DB: What about the idea of mixing wood types? You guys use mostly maple.

Rob: We don’t mix woods, but we’ve done different shell makeups. One that was successful was 8-ply ash.

DB: What did ash bring to the table?

Rob: We found that it sat somewhere between maple and birch. Ash doesn’t have the roundness of tone that maple has. It has an aggressive attack with a nice low-end punch and a bit more sustain than birch.

DB: Why didn’t you continue making them?

Rob: It just didn’t warrant the cost of buying the number of shells we’d have to buy for the amount that we sold. One thing I’ve discovered after twenty-six years of doing this is that people always default to maple.

DB: You were also offering a Chinese-made series, the SL. What happened with that?

Rob: In that price range, you have a slim margin. So if that kit has to be returned for any reason, you’ve lost. We found that we were maintaining that line more than we wanted to, and we’re not a company that wants to put our name on something that may be a problem. After dealing with it for a couple years, we decided to go back to doing what we do best, which is building great-quality, handmade instruments. Advertisement

DB: Have you had any problems with the CL series, since it’s also made outside your shop?

Rob: We never have problems with the CL series. We’re not having them manufactured by the container load. Each drumset is made exactly how we make them here, so if somebody wants a five-piece kit they can get it. If they want a 7×10 tom instead of an 8×10, they can get it. Or they could get a different color. There are a lot of possibilities with that line. It’s not your standard run-of-the-mill import drumset.

DB: What’s different between the CL lug and the SE lug?

Rob: The CL lug is a casting and has a threaded insert inside. The SE lug has a separate insert inside that rotates to align the tension rods, and it’s made here at GMS.

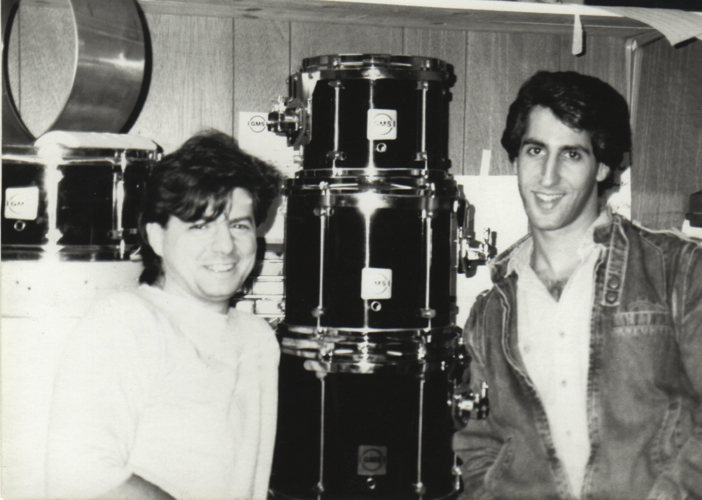

Tony and Rob in the early days of GMS

Tony and Rob in the early days of GMS

DB: How did you and Tony Gallino end up starting GMS?

Rob: It wasn’t a real conceptual thing. I was a machinist, so I would make parts and accessories for my drumset, like things to stack cymbals on top of each other. Back in ’85, there wasn’t really anything like that.

Tony and I used to shop at the same store, the Long Island Drum Center. The owner, Tony Fabiano, introduced me to Tony Gallino because [Gallino] was working on snare drums at the time, and he had some ideas for a lug. We got together and started to develop the Grand Master lug. Then he had a concept for a throw-off. He had it all drawn out, so I made the parts for him. We still use that throw-off today. Advertisement

DB: When did you decide to make a go of it as a company?

Rob: As with everything that we’ve done, it kind of just fell in our lap. In 1987, there weren’t really any companies doing what we were doing—at least not that we knew about. Tony Fabiano would call us up to make a custom snare drum for a customer, and that’s how we started.

Within a year, people were telling us that we should display at the NAMM Show. I called them in September, but they were completely sold out, so we were put on a waiting list. I didn’t think anything of it, but in December we found out that there was a booth for us. We didn’t have any inventory, so we ended up borrowing a kit that we had made for somebody, to take with us. We took a lot of orders at that show. People were appreciating what we were doing.

Then a year and a half later, we met with the Paistes. They were trying to put out drums at that time, but it wasn’t going their way. They liked our concept, and by 1990 they were distributing us. Things took off from there. Advertisement

DB: What was it about GMS that was intriguing everyone at that first NAMM Show?

Rob: It was a combination of things. First of all, we offered any color and size you wanted, which didn’t exist at that time. Most manufacturers had five stock colors and limited sizes. And back in those days there wasn’t a lot of attention to detail, so you often had to take your drums to somebody to be doctored up in order for them to sound good. We shipped our drums to sound that way out of the box. We’re spoiled now by having great products from so many brands. But I think companies like ours helped make [the bigger companies] start paying more attention to what they were doing.

DB: Who were your competitors at the time?

Rob: The only person that I knew who was producing drums like us was Joe Montineri, and the only reason I knew of him was from seeing him in Modern Drummer’s NAMM issue. Then, when we first started going to NAMM, DW began making drums.

DB: As business escalated, was there a point when you had to upgrade your shop or move to a new location?

Rob: We’ve been in this unit since ’91, and we’ve always maintained the hands-on approach, so whatever machinery we had then we still have now. We never got into a “mass build” mentality; we don’t have machines that drill all the holes at once or anything like that. Maybe that makes sense manufacturing-wise, but we look at it more like home-cooked food—it’s made with a little more love. Advertisement

DB: Has anything changed at GMS from the beginning to now?

Rob: As I said earlier, we’re focused more on specific items, as opposed to letting customers choose anything they want. We live in a society now where we’re told what to buy, like Apple with the iPhone. There are two colors and three memory sizes, and that’s it. We’re not that rigid, but our snares are now available in three basic colors. You can still get something custom, but the standards are natural, midnight stain, and walnut burst. That makes it easier for dealers, and those colors are timeless and go well with most drumkits.

DB: What’s the future for GMS?

Rob: I don’t know what the future of the drum business is as a whole, but we’ll adapt to whatever it is. We’ve been doing this for twenty-six years, so we’ve seen the business change in a lot of ways. I think we’re a little better off now that we’ve adopted this model of offering very specific products, like the Revolution, PVS, and Super Vintage snare drums. Those are things that other companies don’t have, and they’re very identifiable to us, so we can hang our hat on that.

DB: Where do you see your position in the industry now? Your reputation and history put you a few steps ahead of many of the newer boutiques.

Rob: We’re not your mainstream drum company. We sell mostly to shops where the guys really get what we’re doing. We’re still boutique, and that will always be our value in the future. When we first started, the concept was: We’re never going to be as big as Pearl; we’ll just do what we do. Advertisement

For more info, visit gmsdrums.com.

(This story originally appeared in the May/June 2013 issue of Drum Business Magazine.)